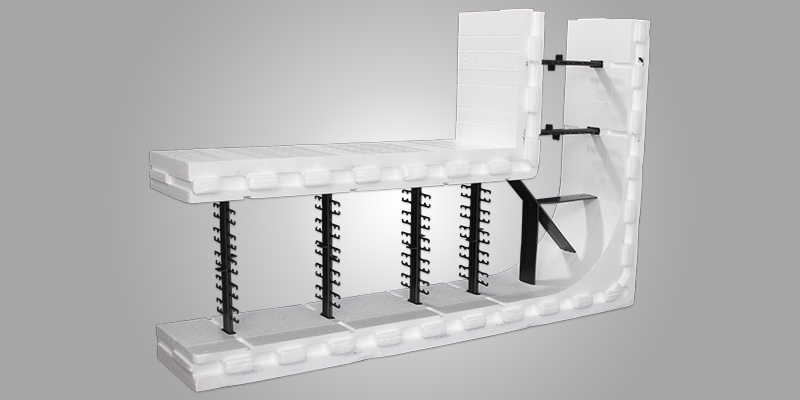

FOX BLOCKS SERIES

Our core product line – this series of ICF products is the basis for a successful build. Used in just about any configuration you can imagine. See configuration options below.

Product Highlights

Unlimited Design Detailing and Finishes

With blocks available in a number of shapes, sizes, and concrete core thicknesses, we can create any design you can dream up. Plus, our wall assembly works with all exterior/interior finishes you choose to use, be it EIFS, traditional stucco, brick, stone, fiber cement siding or drywall.

Unparalleled Comfort and Quiet

Our wall assembly provides indoor comfort and improves a building’s performance characteristics for the interior environment by eliminating moisture intrusion, managing the airflow and allowing for accurate climate control and minimizing sound mitigation.

Strength Against the Elements

Our ICF wall assembly meets and exceeds safety/resilience/durability requirements for Division 03 Concrete, Section 031119 ICF; Whole Building Design Guide (WBDG) Unified Facilities Criteria (UFC) & FEMA-ATFP Federal Military and DoD Standards FEMA-ATFP.

Lifetime of Savings

The performance characteristics of our wall assembly can reduce a building’s heating and cooling cost dramatically (up to 50%) and puts Net Zero Energy goals within reach.

Learn What to Ask About ICF Installation

Want to know more about installing ICF but aren't sure where to start? Our Guide, 13 Questions You Should Ask About ICF Installations, will give you answers to the most important questions about ICF installation, including what types of buildings you can use ICF in, how tall the building can be and more.